If you’re considering switching to LED lighting in your home or office, you may wonder what COB LED strips are. COB stands for “chip-on-board,” These LED strips feature multiple LED chips directly bonded to the circuit board. But that’s only the tip of the iceberg.

This article will go through everything you need to know about COB LEDs, including their advantages and disadvantages and how to install them.

What is COB LED?

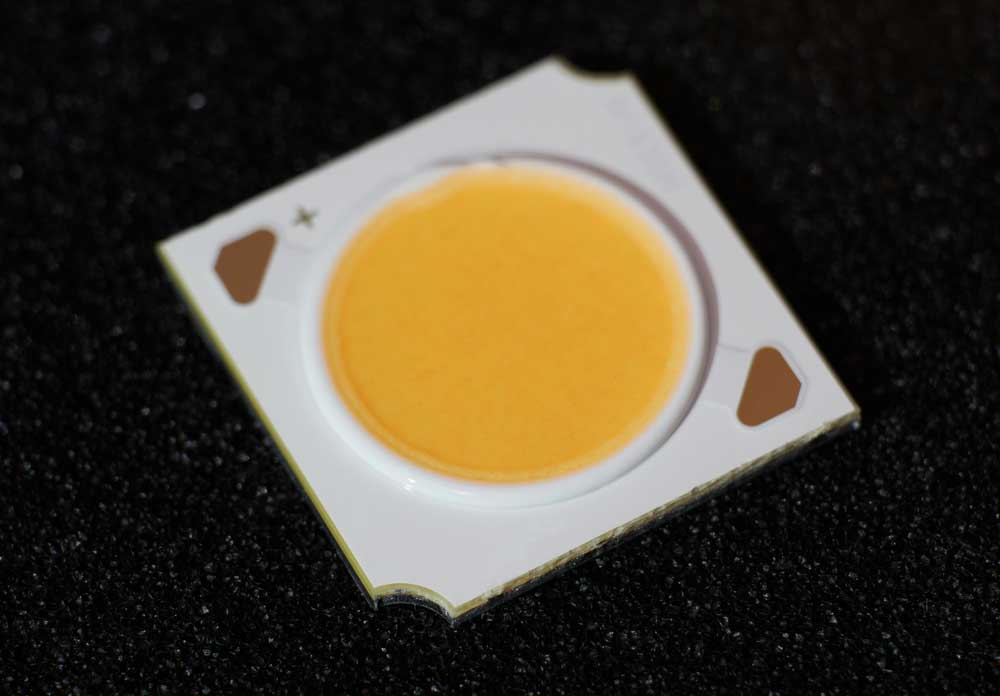

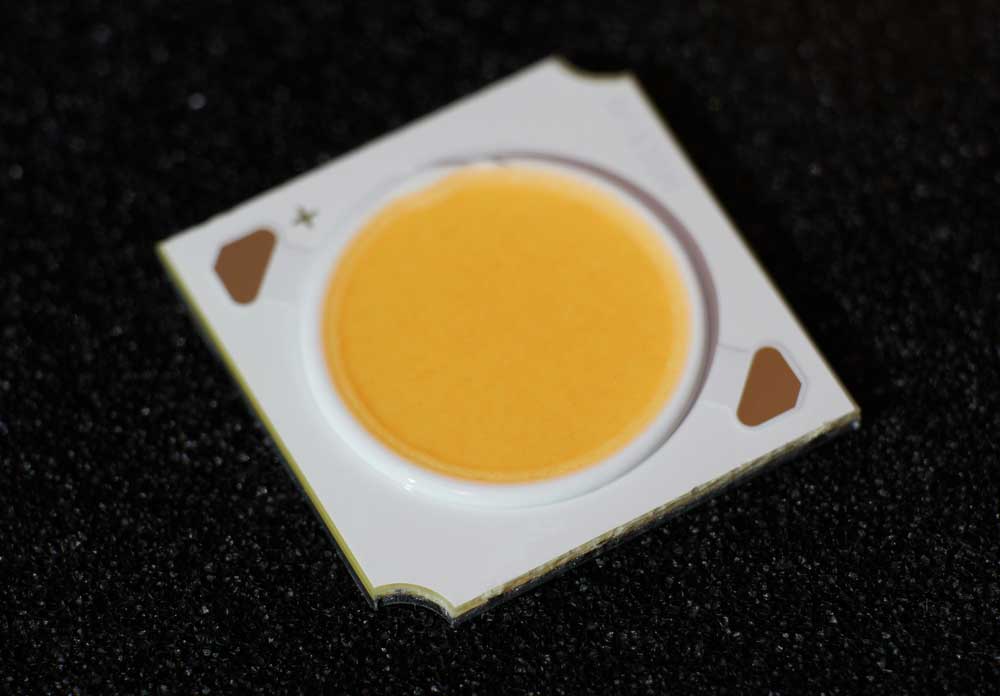

COB stands for Chip on Board – a technology that allows direct mounting multiple LEDs into the PCB (Printed circuit board) to form a single light.

The compact packing of the chips results in higher intensity and more excellent light uniformity. So you won’t notice any spaces between the LED chips.

A COB LED chip

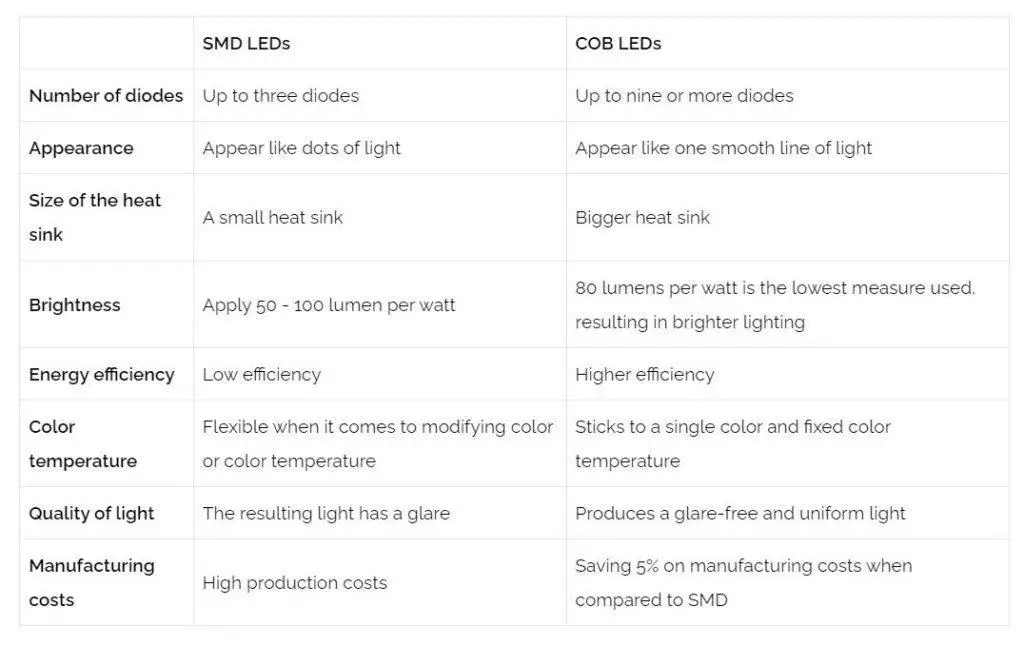

Difference between SMD and COB LED Strips

Now that you know, COB LED consists of several chips integrated on PCB, forming one smooth line of light.

On the other hand, SMD stands for “S” surface mounted devices.” “like COBs, SMD LED strips to use a different type of LED lighting technology and appear like discrete tiny dots along the strip.

Internal Structure of COB and SMD LEDs

In the case of COB chips, manufacturers directly mount the chips on the PCB board, whereas for SMD strips, they mount the chips on a bracket and then solder them to the PCB board.

It means that COB strips can have more chips arranged with a higher density on the exact PCB board length, resulting in a much brighter and more uniform appearance from COB strips than SMD strips.

But what does set these LEDs apart? LeLet’save a look.

SMD LED Strip

COB LED Strip

How Are Flexible COB LED Strips Manufactured?

The manufacturing process begins by creating a PCB, then closely placing each flip-chip LED down the middle of the tape light.

They are so close that you can find up to 512 LED chips in every meter of the strip.

After the flip-chip LEDs are in place, a phosphor coating covers the light strip. This phosphor layer helps to balance the color temperature and acts as a protective layer for the LED chips underneath.

Benefits of COB LED Strips

Here are some advantages of COB LEDs:

Uniform Light, No More LED Hotspots

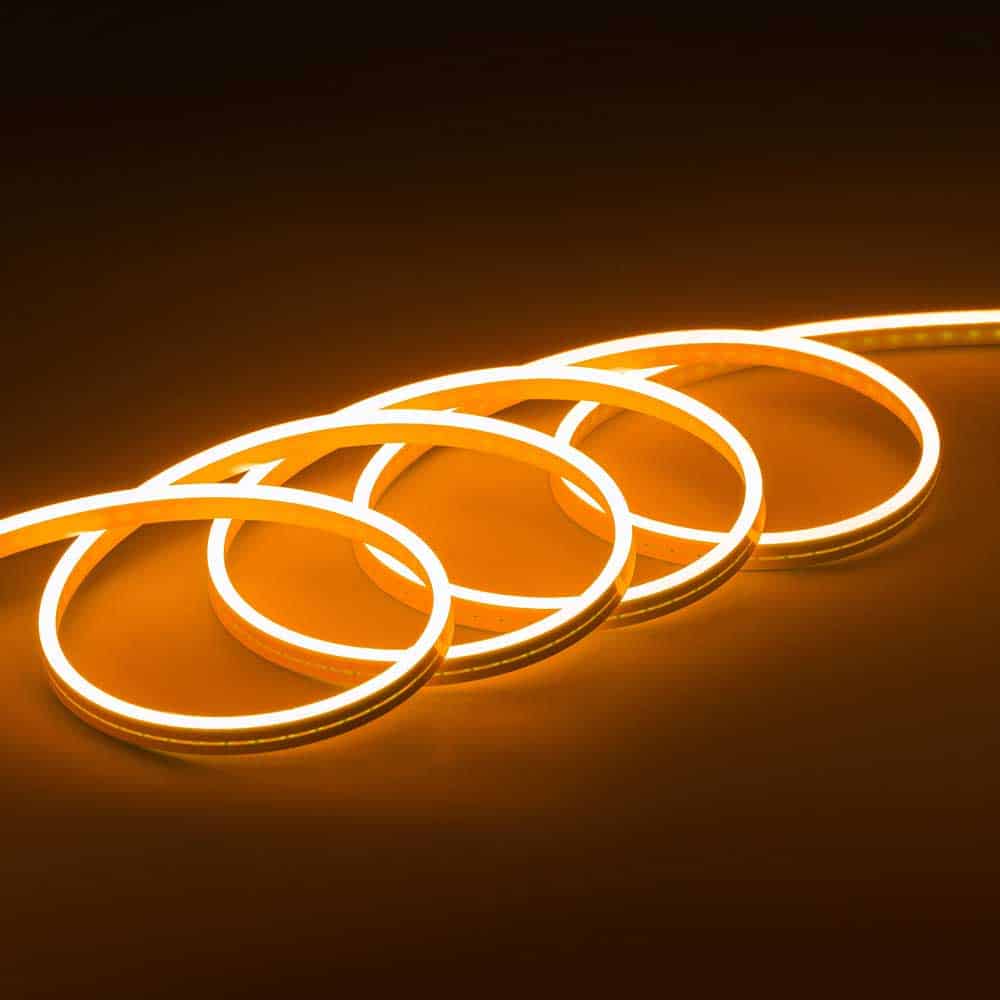

COB strips lack hotspots, and LED hot spots usually refer to inconsistently bright areas from which you can tell where the light comes. Instead, this light strip forms a smooth line of light.

Wide Beam Angle

COB LED strips to have a wider beam angle of 180º degrees, while the traditional SMD strip lights have a beam angle of only 120º.

Due to the COB’side angle, the light strip illuminates a wide range and produces an easy-to-adjust, uniform illumination.

More Flexible

COB LEDs are very flexible in that you can curve them around corners and even bend them into shapes to fit into tighter areas. The small size and the uniform weight distribution of the diodes are the reasons behind the improved flexibility of COB LEDs.

More Stable, with Fewer Problems

COB LEDs are directly connected to the FPCB (Flexible Printed Circuit Board), eliminating the need for a gold wire that easily breaks.

The circuit design of COB LEDs uses three chips in parallel, which helps to ensure that even if one or two chips are bad, your COB strip will continue to light.

More Efficient, with Less Heat

COB LEDs produce less heat than traditional strips since the copper plate has its heat dissipation function, which helps speed up the process.

On top of that, the COB chip lies on the PCB board. And this dissipates the chipset even faster by transferring it to the board.

Stronger Anti-static Capability

COB strips have a more vital anti-static ability than SMD strip lights, so there’s a slim chance that the electrostatic discharge can damage them.

Can Be Cut

COB LEDs are perfect for DIY and small projects as you can easily measure the required length and cut it to any size you need.

Drawbacks of COB LED Strips

Difficult to Maintain The Consistency of Color

Maintaining the color consistency of a COB LED strip is difficult because there is no binning machine on the market.

It means that all manufacturers only sample the LEDs to ensure color consistency.

So, ensuring that 100% of COB LEDs are within the 3-step color tolerance won’t be easy.

Lower Luminous Efficiency

The COB-led strip has a brightness of 120LM/W; for some people, this may not be high enough.

If you need a higher light efficiency, then it won’t probably be the best option.

Lower Power

Although COB LEDs contain many chips, this doesn’t necessarily mean they produce very high power.

The maximum power allowed for COB led strip is only 15W / m. Applying more energy will make it harder to dissipate the heat generated by the chips and could shorten the strip’s life.

Characteristics of COB LED Strips

24V Powered Strip

COB LED strips to use 24VDC instead of 12VDC, and the higher voltage is necessary to accommodate all the diodes within the strip.

Using 24VDC LED strips offers various benefits, such as a longer lifespan since these strips run with half the current of 12V LED strips.

It also allows for less voltage drop along the length of the strip; a voltage drop is when the voltage decreases along the light strip.

In case of voltage drop, you will notice that the light at the starting part of a prolonged LED light strip is brighter than at the strip’s end.

It means the light will be more consistent no matter where you are on the strip, making them ideal for long continuous setups.

Note: Ensure having a 24VDC power source to use these strips properly.

Color Options

COB LEDs come in various colors to find the perfect one for your project. Standard white outputs include warm white, neutral white, and cool white.

If you’re looking for something a little more colorful, you can also get the red, blue, and green colors of the COB LED. Many customization options exist for color temperature and even RGB and RGBW lighting.

IP grades

COB LEDs come in different IP ratings, including IP20, IP52, IP65, IP67, and more.

When purchasing a waterproof strip light, it is essential to understand the different IP grades and how they can affect your usage.

IP20 is the lowest grade and is not waterproof at all. This strip is best suited for indoor use in cabinets, bedrooms, or living rooms.

The IP65 grade has a silicone tube sleeve and is perfect for the outdoors. The IP65 grade has a silicone tube sleeve and is ideal for outdoors.

It can handle low water pressure, so you can also use it in damp areas hassle-free as long as you don’t submerge it into the water.

COB LED Strip Light Application

You might be wondering about the different uses of COB LEDs. So let me clue you in a bit. Here are some potential benefits and applications for them:

- Street lights

- Home light fixtures

- High-bay lighting

- LED Lamps

- Downlights

- Simple lighting for passages and hallways

- Playground lighting

- Replacement for fluorescent lighting

- Smartphone camera flash

Using COB Tape light in Home Decoration

How to install the COB-led strip light?

1. Clean the surface you are attaching the led strip to

2. Remove the adhesive backing on the led strip

3. Line up the led strip with the edge of the surface

4. Press the led strip down onto the surface

5. Connect the power supply to the led strip. If the COB strip is cut and there is no primary connecting wire, you need to use a soldering iron to weld the two sides of the COB-led strip.

You can also use a “B” ard to Wire Connector,” ” small connector that you can solder onto the end of the COB-led strip.

6. Now, you can turn on the power and enjoy your new COB-led strip light!

The installation of COB LED strip

Summary

In short, COB LEDs offer various benefits over traditional LED strips. Many customization options exist for color temperature and even RGB and RGBW lighting.

With so many potential uses, COB LEDs are an excellent option for any task lighting with many possible benefits.

We hope this article has provided some valuable information to you. If you have any questions, please don’t hesitate to contact us.