LED strip lights have several applications in indoor and outdoor areas in homes and commercial spaces. Powering these LEDs requires a reliable and well-designed driver that can operate the chips without causing burnout or decay. Constant current vs. constant voltage drivers is the most typical devices for this task. These two drivers have several differences that determine their applications. We will compare a constant current vs. constant voltage below to see how they stack against each other. Let’s get right into it!

Constant Current vs. Constant Voltage: What is an LED Driver?

An LED driver is an electrical device that regulates the current flowing through LEDs. It can be either a constant current LED driver (CC), constant voltage LED driver (CV), or both.

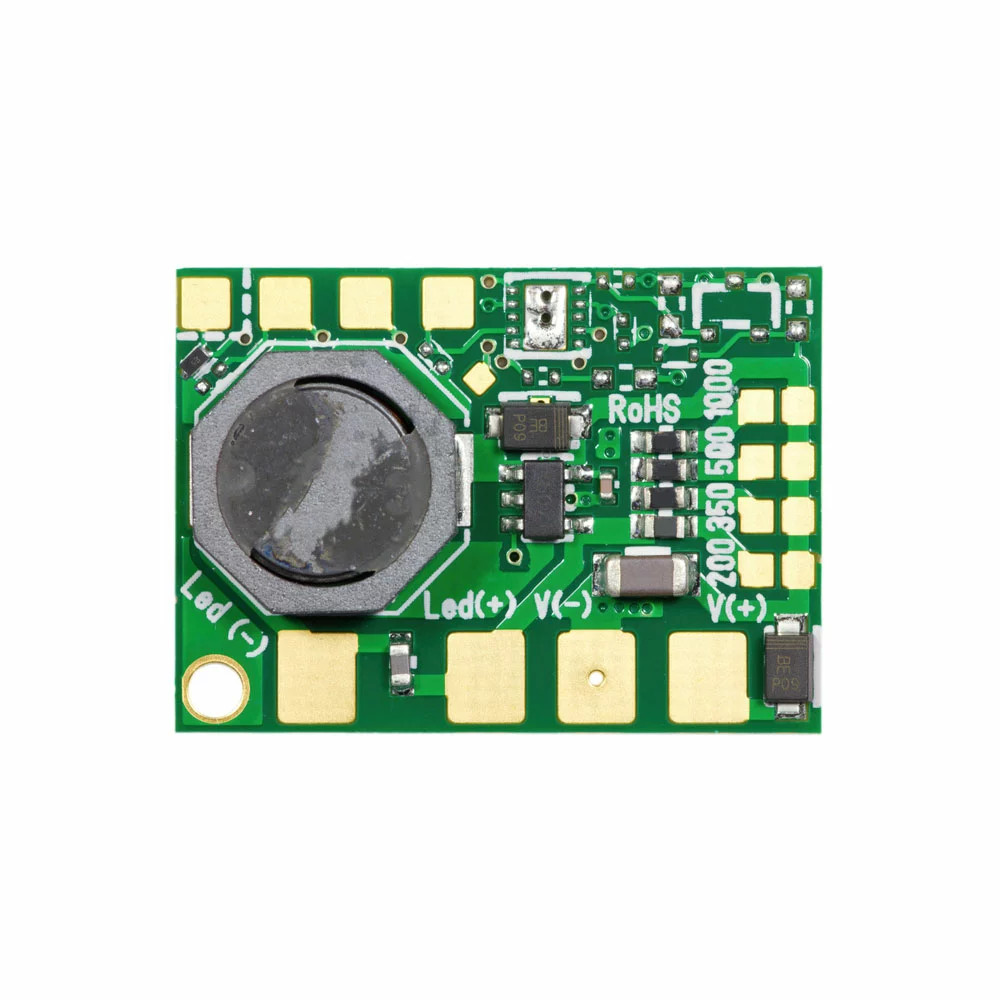

An LED driver

Constant Current vs. Constant Voltage: What is a Constant Current LED Driver?

Constant-current LED drivers produce a constant output current with a varying output voltage. The device fluctuates the voltage in the electronic circuit to ensure the current output remains constant.

This design results in a higher flow of current that makes the LEDs shine brighter. However, if you don’t regulate the current flow, the LEDs will draw more current than they can handle, causing premature burnout due to the excessive heat.

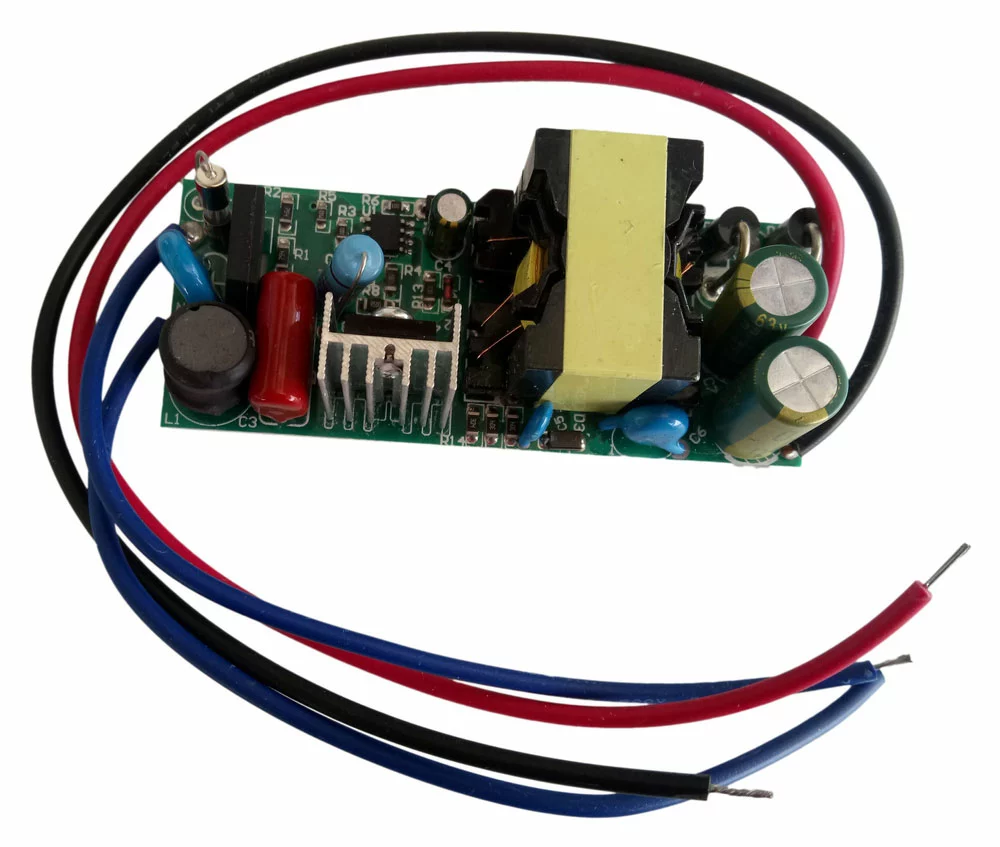

An LED driver’s printed circuit board

And if they don’t burn, the thermal runaway can reduce the LED’s lifespan and quality. Therefore, running a constant voltage driver is better, but the CC type still has several applications.

When is a Constant Current LED Driver Needed?

Constant current drivers are ideal for LED lights that feature the direct drive method. Direct drive implies the driver’s current flow powers the LED circuit directly. Direct drive current is typical in large or high-powered LED installations for industrial lighting, commercial LED displays, backlighting, and LED signs.

Commercial LED lighting on a mall’s roof.

You can use this constant current power supply with a chain of LEDs connected in series or a single bulb. These drivers are also less complex and highly efficient, making them the ideal option for brightness and light quality control. On top of that, you can tune the driver to run the LEDs more efficiently.

Constant Current LED Driver Pros and Cons

Pros

- Affordable

- High efficiency

- Suitable for high-power LEDs

- Help create light with a consistent brightness

- Enable easy light quality and brightness control

- Avoid violating the max current limit for a specific LED to prevent premature burnout.

Cons

- Provide uneven current (brightness) in parallel LEDs

- One light bulb failure will cause the others to go off in a string series

What is a Constant Voltage LED Driver?

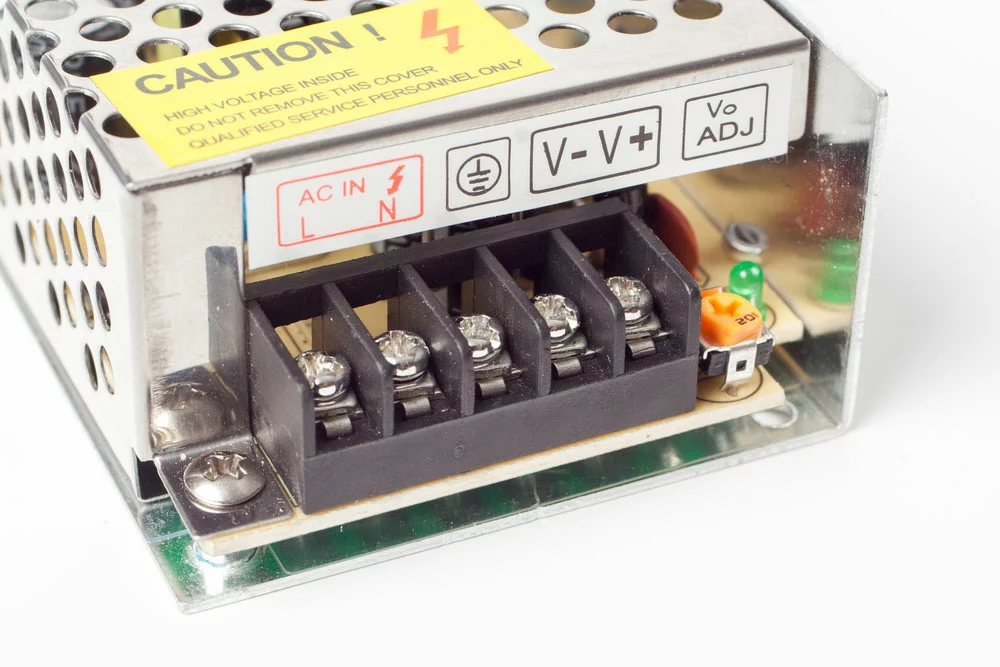

A constant voltage LED driver is the opposite of a CC driver because it varies the current, but the output voltage remains constant. Usually, it produces a single current output voltage as DC (direct current).

The typical ones are 12V DC and 24V DC, and most get their power supply from the standard line voltage (120V AC). Therefore, the units convert AC to a much lower direct current voltage (12 or 24V DC). This output voltage remains constant regardless of the current load, increasing efficiency and longevity.

The connections of an LED strip’s power adapter. Note the line AC input and the stepped-down output voltage.

When is a Constant Voltage LED Driver Needed?

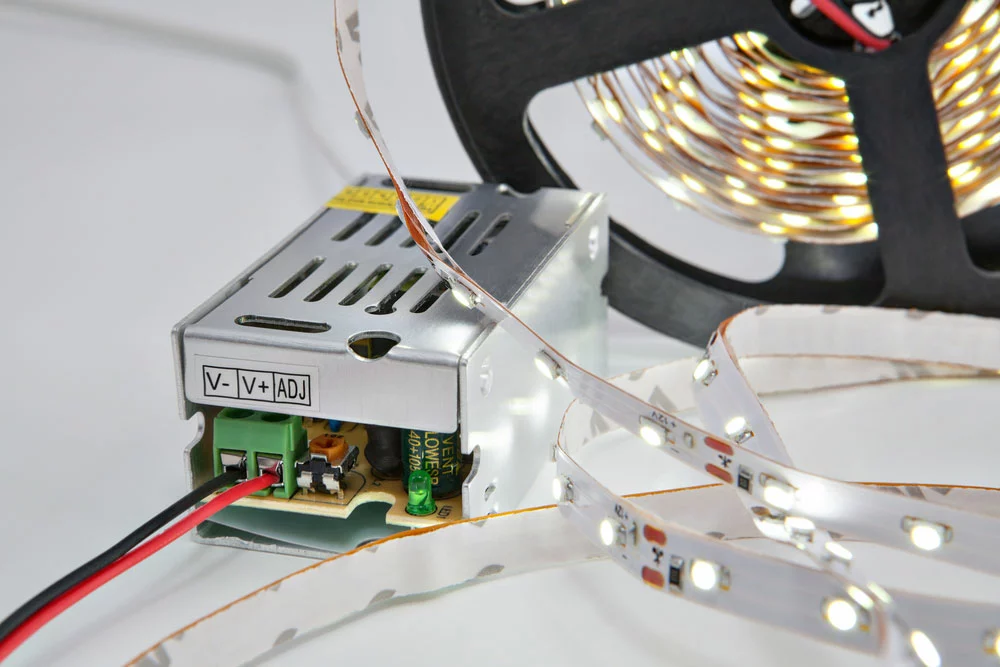

A constant voltage power supply is suitable for running several LEDs, such as LED strips, in parallel. Usually, the drivers feature a regulator or current limiter built in to keep the voltage output fixed while the current varies. Each current limiting resistor is in line with its strip to prevent variation in the LED voltage.

Current limiting resistors in an LED circuit run by a constant voltage driver

From the diagram above, you can see that cutting some parts of the LED strips will not affect other parts of the circuit. The voltage on each string remains constant.

For instance, if you have a 500mA driver running five strips, each gets 100mA. Cutting one piece does not mean the excess current will go to the other four. The built-in circuitry will regulate the current, so you only have to ensure you use the correct DC voltage driver value (12 or 24V DC).

Can I Use A Constant Voltage Driver Directly For LEDs?

Unlike with a constant current power supply, you cannot connect a constant-voltage supply to LEDs directly. With a constant voltage, the current will increase gradually, raising the temperature inside the LED. An increase in temperature lowers the efficiency of the LEDs, and it can quickly rise to 80°C or 90°C if the heat dissipation mechanism is not good enough.

An LED driver with a voltage converter

For instance, a 3.3V constant voltage source providing a 20mA load current at room temperature can increase the current to 37mA with no extra brightness. Instead, the higher current will exit the LED as heat, decreasing the LED’s lifespan and increasing attenuation.

Similarly, if the temperature drops to -40°C, the current will decrease by about half to 10mA, and the light output will reduce. The temperature issue becomes worse when running high-power LED chips.

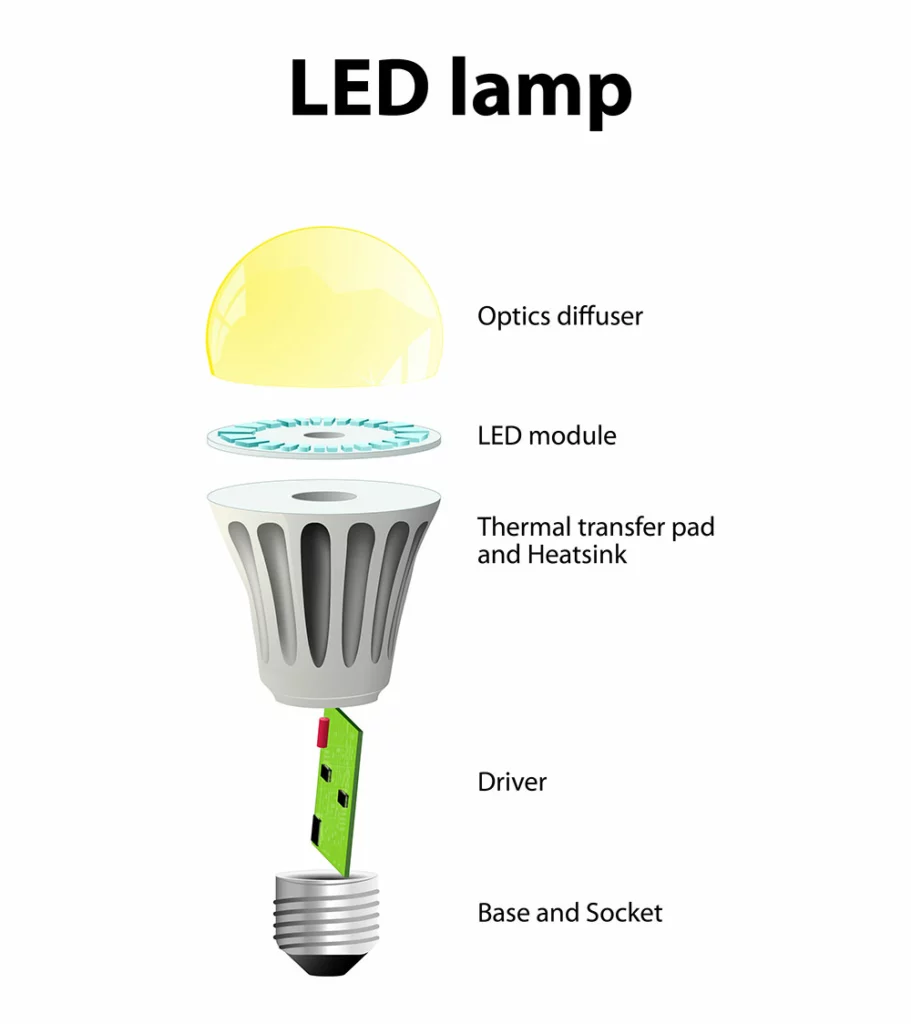

An LED driver/power supply

Therefore, besides poor heat dissipation, constant voltage power supplies are the main cause of LED light decay.

However, you can fix this issue by introducing current-limiting resistors in the circuit. Ensuring the LEDs get a constant current source keeps the system steady even as temperatures rise with an increase in voltage. Thermal runaway and overdriving reduce the LED’s lifespan, so preventing them is crucial.

The internal parts of an LED bulb. These units also have drivers

Constant Voltage LED Driver Pros and Cons

Pros

- Can tolerate faults (one strip light failing does not affect the others)

- Easy and flexible installation when dealing with multiple strips or lights

- Fewer models to work with (12 or 24V DC)

- Can be affordable in large-scale LED lighting applications

- Standard technology for LED circuit design and installation engineers

Cons

- Lower efficiency than the constant current driver

- The driver or light strip must have a current limiter

Constant Power LED Drivers

Recent innovations in LED driver technology have led to the development of the constant power LED driver, a device that controls the output current and voltage to supply regular power.

An LED driver board

Controlling these two variables enables the driver to power the LEDs to achieve optimum brightness and junction temperature. Additionally, these drivers are easily configurable and have more application areas.

Constant Current vs. Constant Voltage: Which Driver Type Do You Need?

Consider the following criteria to pick the best-LED driver for your project.

- LED current and voltage

- LED driver application

- Efficiency

- Ease of installation

- Safety and energy efficiency standards

A constant voltage LED driver is sufficient for small LED lighting applications. However, as the number of LED strips increases or the load rises, manage the drive current using a constant current LED driver.

An LED light panel with its driver

But from a practical standpoint, constant power LED drivers are the best option.

Wrap Up

In conclusion, constant-current and constant-voltage are two of the most typically used LED drivers, and each excels in different applications. Although constant-power LED drivers give more flexibility, the two units are still practical in many applications. That’s it for now! If you have any questions or comments, contact us for more information.