Color consistency plays a huge role in the perceived light quality in interior spaces. So when buying luminaires, keep in mind their light color output is critical, especially if you want to install multiple light sources in one continuous area. The MacAdam ellipse plays a significant role in helping us understand the color differences in LEDs because it helps standardize light colors. We will analyze it in detail to show you how it helps create color-consistent LEDs. Let’s get right into it!

What is a MacAdam Ellipse?

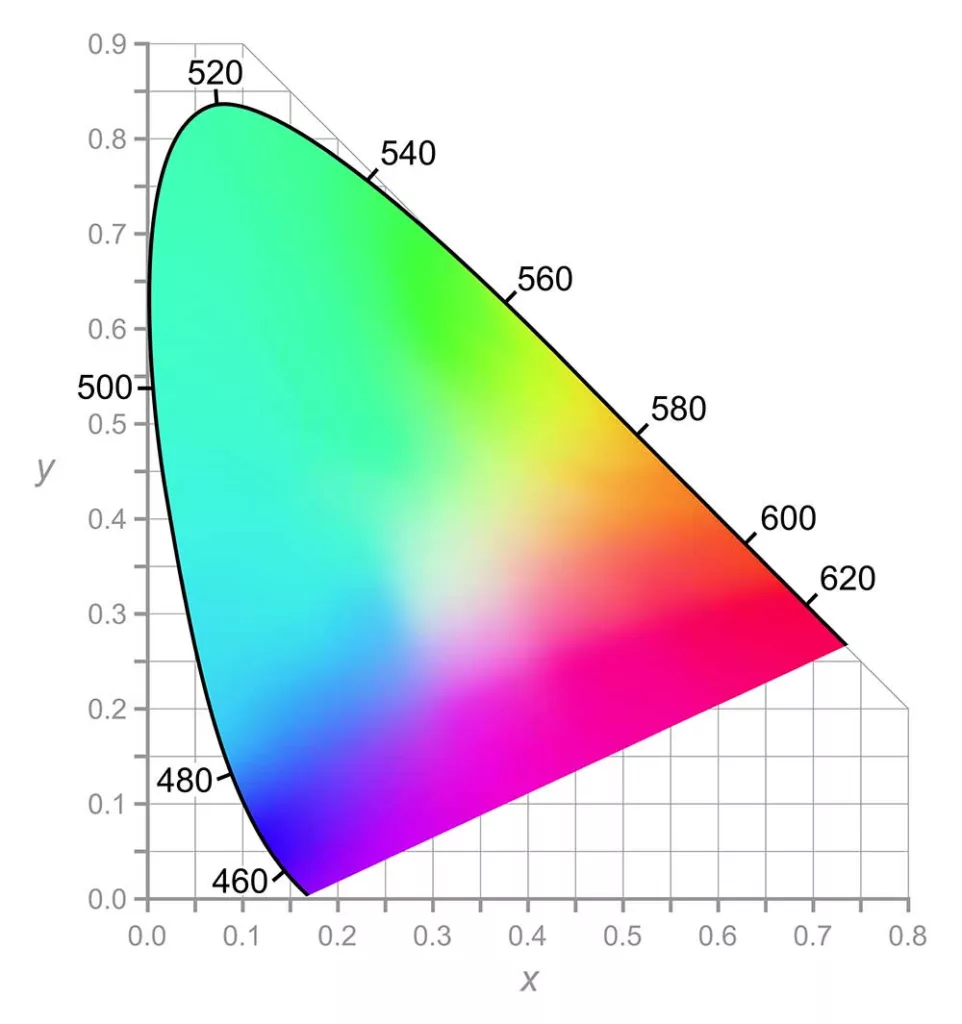

A MacAdam ellipse is an area on the chromaticity diagram that contains all indistinguishable colors. The CIE chromaticity diagram has been applicable since 1931, hence its name, the CIE 1931 color spaces.

The CIE 1931 XY chromaticity diagram

The name MacAdam comes from David MacAdam, a scientist who experimented with color perceptions and chromaticity differences. He then transferred the results to the flat chromaticity diagram and measured 25 ellipses, with the contour of one representing the JND (just noticeable differences) in color matching.

The experiment proved that an average human eye could not spot the color differences in the ellipse regions from the MacAdam ellipse’s center.

Standard Deviation Color Matching (SDCM) has roughly the same meaning as a MacAdam ellipse. LED lighting uses color deviations in MacAdam/SDCM ellipses to define a light source’s color precision.

What is a MacAdam Step?

A 1-step MacAdam ellipse is a zone in the CIE 1931 XY chromaticity space where a human eye cannot detect color variations. Therefore, it is the elliptical area where observers identified and determined that it has the same color.

The experiment showed that humans have a more challenging time spotting chromaticity differences in green color. So you will notice ellipses in the green section are broader than those in the blue region. Therefore, these green zones have more expansive MacAdam steps than blue color zones.

What is the Importance of Color Consistency in LED Light Sources?

The human vision system has highly tuned senses for color perception. If the chromaticity coordinates of two LED lights fall within a 1-step SDCM ellipse, you will not observe any color difference. If the variation falls in an area twice as large (2-step MacAdam ellipse), you will spot slight color differences. A 3-step zone will show more chroma differences.

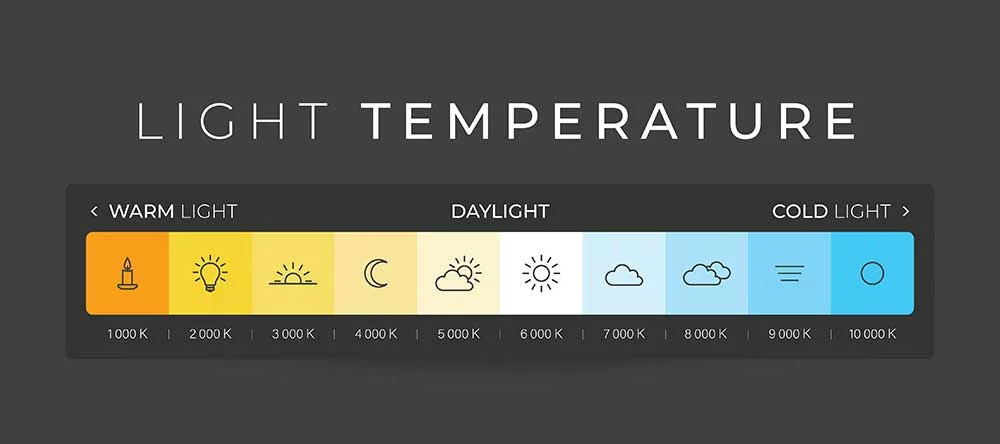

If we consider the size of a 1-ellipse step to be 3,000K color temperature, then the CCT range will be +/-30K. So it will take a tiny change of +/-30K to detect the light sources are color inconsistent.

The white color temperature scale

Here’s how the differences fare.

| SDCM/MacAdam Ellipse | Visibility |

| 1 SDCM step | Almost zero visible deviations |

| 2 SDCM steps | Deviations noticeable using instruments |

| 3 SDCM steps | Few differences noticeable by the human eye |

| 4 SCDM steps | Visible deviations |

| 5 SDCM steps | Clear and visible deviations |

Color Consistency Outdoors

But the importance of color consistency depends on the application. For instance, detecting deviations in outdoor lighting is more challenging because the visual receptor experiences the Purkinje effect.

The effect defines the tendency of the eye’s sensitivity to peak illuminance shifting towards the blue light spectrum in low light levels. The diminished color detection plus wide spacings in outdoor lighting make color consistency a non-critical factor in street lighting, parking lots, and other exterior lights.

Parking lot LED lighting

Color Consistency Indoors

However, color consistency is critical in indoor spaces. For instance, the diffusers and lens should project color in the same MacAdam step when illuminating an area using wall sconces. Similarly, wall-wash luminaires should glow in the same SDCM step to prevent noticeable differences.

Variations extending over a 2-step MacAdam ellipse affect the observer’s experience. Not only are they visually distracting, but they also create an impression of poorly maintained or designed lighting.

And this effect can negatively affect your business. Think about how the visual distraction and low-quality lighting will look when reflecting off cars in a dealership or fabrics in a fabric store.

Clothes store lighting

What is LED Binning?

Although color consistency is vital in interior lighting, the unfortunate thing is that manufacturers can’t build LED lights with brightness and color temperature consistencies.

So the only logical thing to do is optimize the production process by sorting the LEDs using color after production. This sorting process is known as binning. LED light sources with similar color deviations separate and fall into different bins. So LEDs in the same collection have the same color temperature.

A customer selecting LED bulbs in a DIY department store

This process is expensive and complex, but it ensures you get LEDs without unpleasant color temperature differences. So if you encounter cheap LEDs, chances are they will have color differences in a specific product line.

Can ANSI and CCT Standards Help When Selecting Lighting Bulbs?

You can define the color of light for LEDs and other light sources using either of the following.

- Coordinates on the flat chromaticity diagram graph

- Spectral power distribution

- Correlated color temperature (CCT)

The CCT is a number defining a light source’s chromaticity proximity along the Planckian Locus (blackbody curve). With incandescent bulbs, the CCT changes from deep red to orange, yellow, white, then bluish-white as the filament glows hotter.

An incandescent light bulb

But LEDs convert the diode’s blue light to white using a phosphor layer. This white light can vary from warm to cool.

LED bulbs

You can correlate the color from these light sources to a point on the blackbody curve with a resulting CCT.

The ANSI documented the incremental color steps on that color spectrum with boxes or regions along the curve to define the tolerance levels allowed for white light-defined CCTs.

The curves are 6,500K on the blue end side and 2,200K on the warm end side. And we define each ANSI or quadrilateral bin using the following factors.

- A center point near or on the blackbody curve

- Deviations below and above the curve

- Color temperature tolerances on the curve

The broadest ANSI bin allows seven MacAdam steps, and an LED’s color coordinates must be within these predefined bins to meet any CCT criteria.

Wrap Up

As you can see, the MacAdam ellipses explain the science behind color difference specifications. The regions on the CIE chromaticity diagram are critical for LED binning and also have a role in defining the ANSI standards for light bulbs. But remember, low-quality bulbs can have noticeable color differences on a single product line. So always choose high-quality LED lights. That’s it for this article, if you have any questions, contact us for further details.